AI optical quality inspection

What if...

... your existing often expensive and not really capable optical inspections are suddenly error-free and reproducible?

Human failure was yesterday!

Are you in doubt?

We'll show you!

Digital Process Data Acquisition

&

Shopfloormanagement

It has never been so easy to create transparency! This is the core statement of our partner. DIGITAL RESULT.

Unfortunately, even today there is still manual or, in the worst case, no process data collection at all in many areas of production. No matter whether defect figures, machine data, downtimes, test results etc..

We experience time and again that efficient problem solving and reaction to trends cannot occur if the data basis is missing. Tally sheets, different data collection systems and the eternal desire to combine everything in ONE system often lead to a situation where you are looking for a 120% solution (the "egg-laying willow sow") but actually realise less than 30% of your potential. And by the way, the "egg-suckers" are often very expensive and take years to implement.

It doesn't have to be!

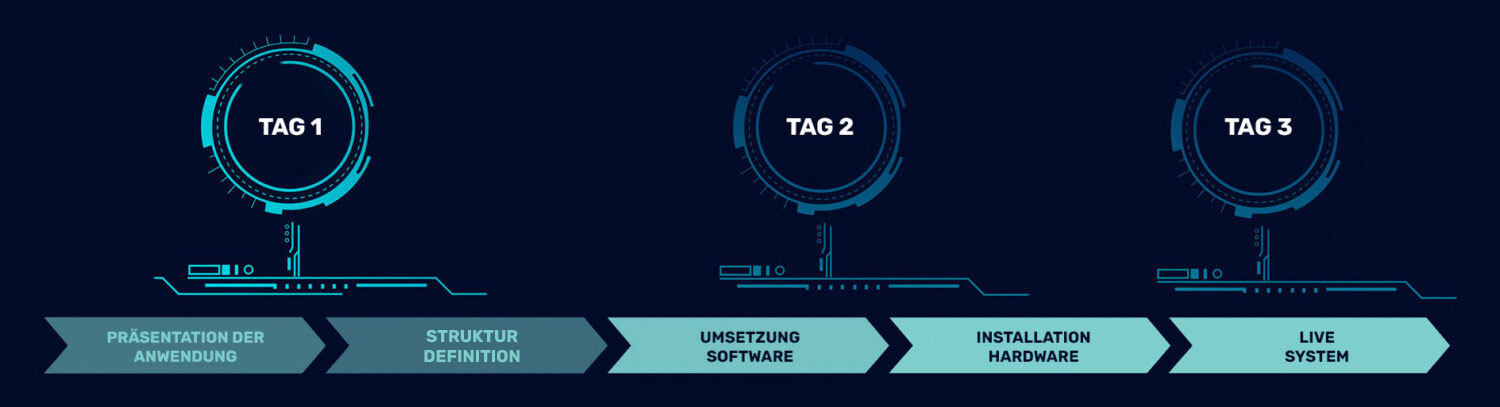

After only 3 days, your employees can easily and uncomplicatedly record process data via tablets. This data can be visualised on dashboards at any time and from anywhere. Z. B. auf einem 80“ großen Touchdisplay direkt in ihrem Shopfloor.

PRESENTATION STANDARD

APPLICATION

STRUCTURAL DEFINITION

SERIAL

LIVE SYSTEM

Satisfied customers of this solution